Protein remains a cornerstone in every diet, with global demand continuing to rise. Embrace the demands of tomorrow with world-class automation technology that enhances the productivity of your workforce, while delivering consistent, high-quality beef, pork, poultry, seafood and plant-based protein to meet the needs of consumers around the world.

Transitioning from Manual to Digital-first Operations

Assessing protein processors’ digital transformation progress

Rising costs, relentless demand and labor shortages are adding pressure to meat, seafood and poultry processors. With varying methods to overcome challenges, assessing the current state of protein processors' digital connectivity is an important first step in evaluating solutions for digital transformation.

There is an appetite for automated business solutions and advanced computing which can help manufacturers more effectively generate and utilize data. And the foundation for digital advancements is already in place among many protein processors.

Optimizing Yield and Throughput

Offering high quality, while keeping costs low and throughput high

New York strip, tenderloin, chops, breast meat, and filets are not only delicious but some of the most valuable and expensive cuts for meat processing. To maintain profitability, meat processing facilities need workforce and automation solutions that effectively manage costs - that starts with maximizing the value of these cuts, through precision and speed.

Some leading meat processing plants are delivering value by adding robotic capabilities that are fully managed through their existing line controller to deliver added precision without adding complexity. Other companies are implementing independent cart technology that provides dynamic, flexible routing to minimize bottlenecks, maximize speed and unlock new capacity.

These companies can overcome rising costs and non-uniform raw material dimensions, shapes and weights to provide a more consistent, high-quality product, which can result in profitably. Additionally, these companies can more effectively route product throughout the facility to reduce bottlenecks and improve overall line efficiency.

Improving Workforce Effectiveness

Accelerating new hire time-to-value and worker retention

Price pressure and competition for skilled workers is fierce in the protein industry. To be successful, meat, seafood and poultry processing facilities must find better ways to capture more value from the equipment on their plant floors – and attract, train and retain workers.

One approach is to attack productivity from several angles, like focusing on fewer, shorter downtime events, increased first pass quality, and faster Mean Time to Repair (MTTR). We are also working with global meat processors to augment their limited workforce with:

- Simplified, integrated robotics

- Precision, advanced motion

- Productivity improving machine safety

Manufactures are also using creative solutions to help train and retain staff, like Augmented Reality (AR) and Virtual Reality (VR). Using this type of learning experience can help increase knowledge retention, reduce training time and upskill the workforce.

Beefing Up Results in Meat Processing

40%

Energy reduction through improved machine design and accuracy

80%

Or more OEE with digitalization and AR-trained workers

4000

Product configurations at 100 cases/minute with smart, agile production

Leveraging Technology to Drive Next-level Productivity

Deploying next-generation software to overcome challenges and satisfy requirements

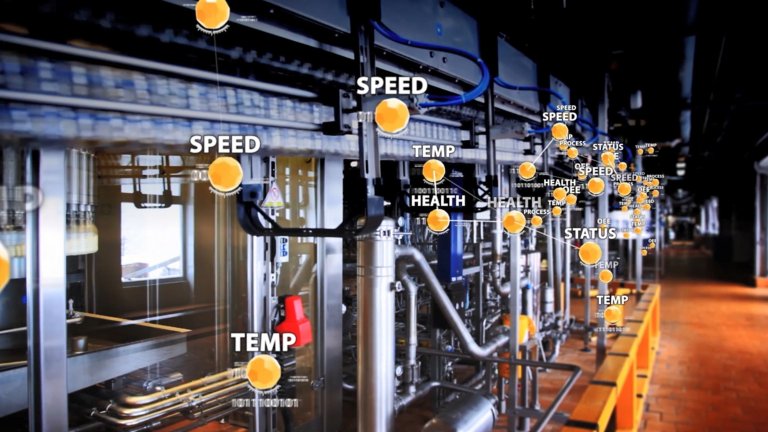

Let’s face it, the manufacturing environment is changing and becoming more complex every day. Consumers want increased visibility about your products, regulators want increased information about your meat processing methods, and shareholders are demanding more sustainable operations. The common underlying theme…information.

Cloud-based technologies such as Plex® manufacturing execution system (MES) or Fiix® computerized maintenance management system (CMMS™) provide your team with the information they need at their fingertips, with the flexibility to quickly scale with your business needs.

The result is increased visibility to machine performance, inventory levels, maintenance requests, quality control, energy usage and more. Use this information to your advantage to build a more robust, sustainable operation.

Seafood, Poultry and Meat Processing Solutions

Discover how the industry uses technology to overcome challenges that impact their bottom line

Moving to Plant-based Meat Production

Producing sustainable protein, while driving costs down

Changing consumer preference for healthy and eco-friendly options are driving unprecedented growth for plant-based meat production. However, operators face unique challenges to deliver high-quality proteins that look, smell, and taste like their animal counterparts.

Leverage the power of IT and OT integration to achieve consistent batch control, integration with suppliers, and operational control that drive down cost and increase consumer adoption.