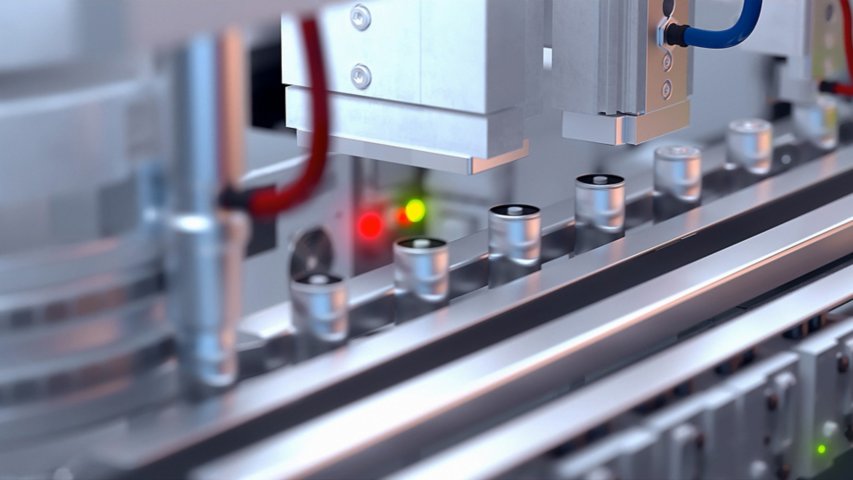

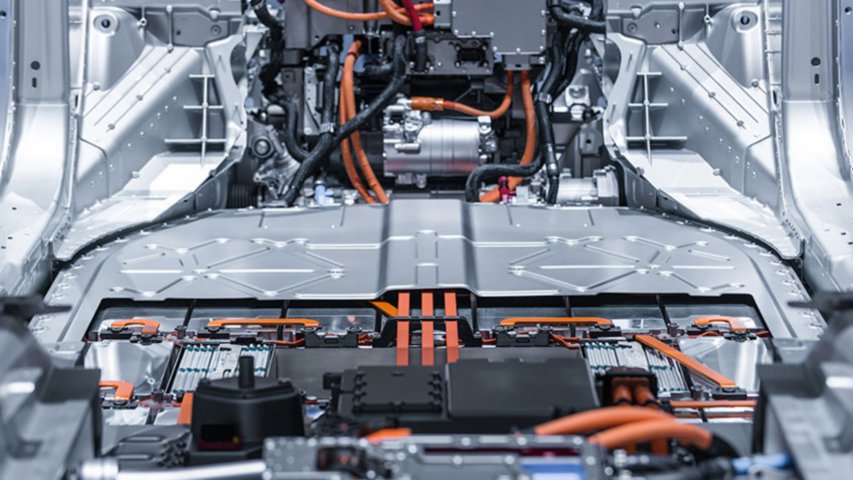

Boost Battery Production

While still small compared to the ICE market, the market for Electric Vehicles is accelerating at an increasing rate, with all Automotive Manufacturers now either having or developing Electric Vehicle solutions – at last count, almost 500 different EVs. Battery manufacturing investments must be managed to allow maximum flexibility for change and maximum return on investment. This, in turn, is driving demand for new Gigafactories, which is no easy undertaking. We can be your battery manufacturing partner and help create a Connected Enterprise that harnesses the value of today’s information technology innovations in manufacturing and industrial operations.