Best Selling

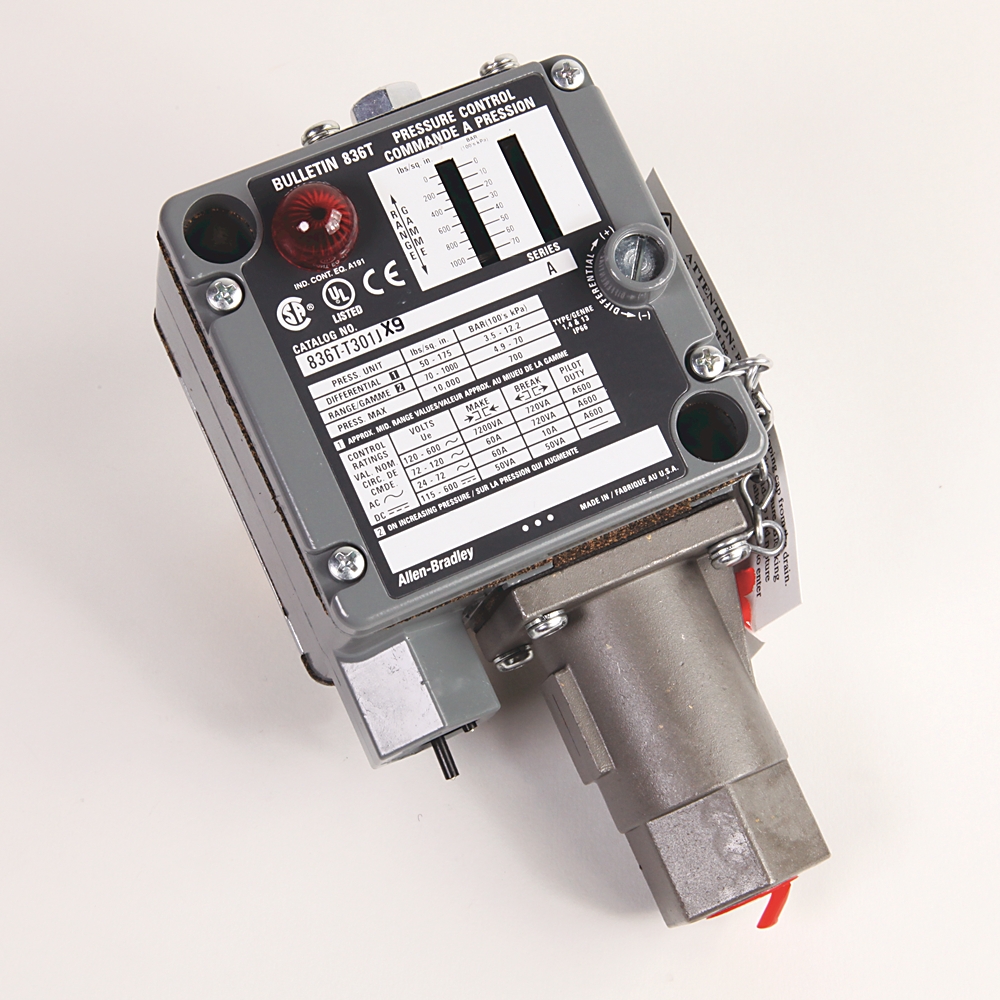

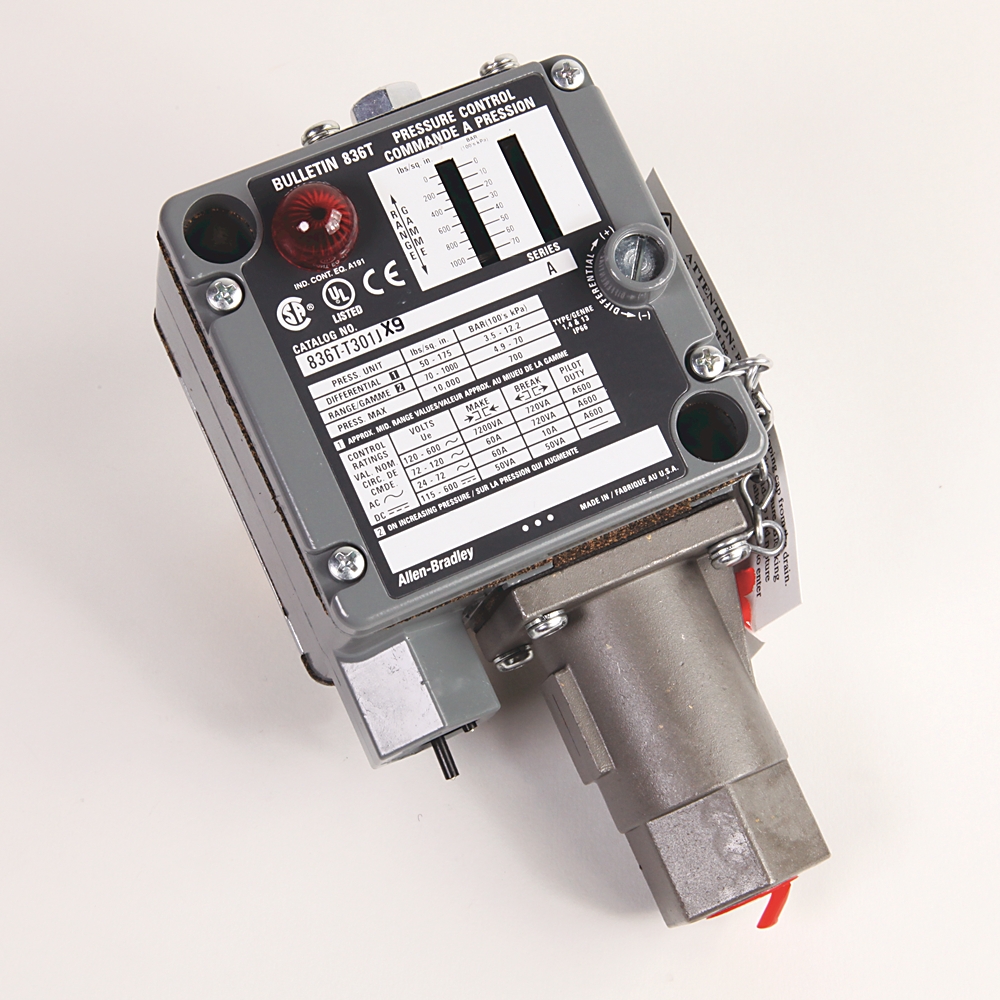

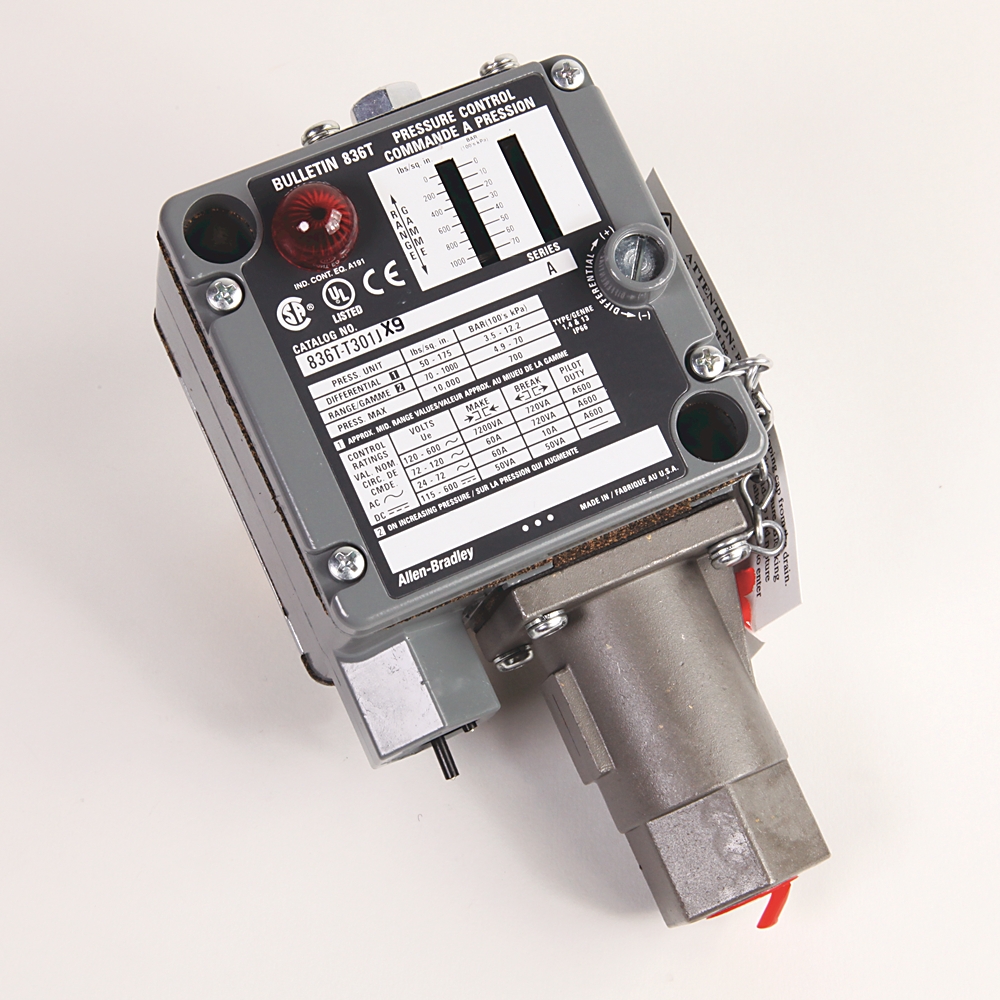

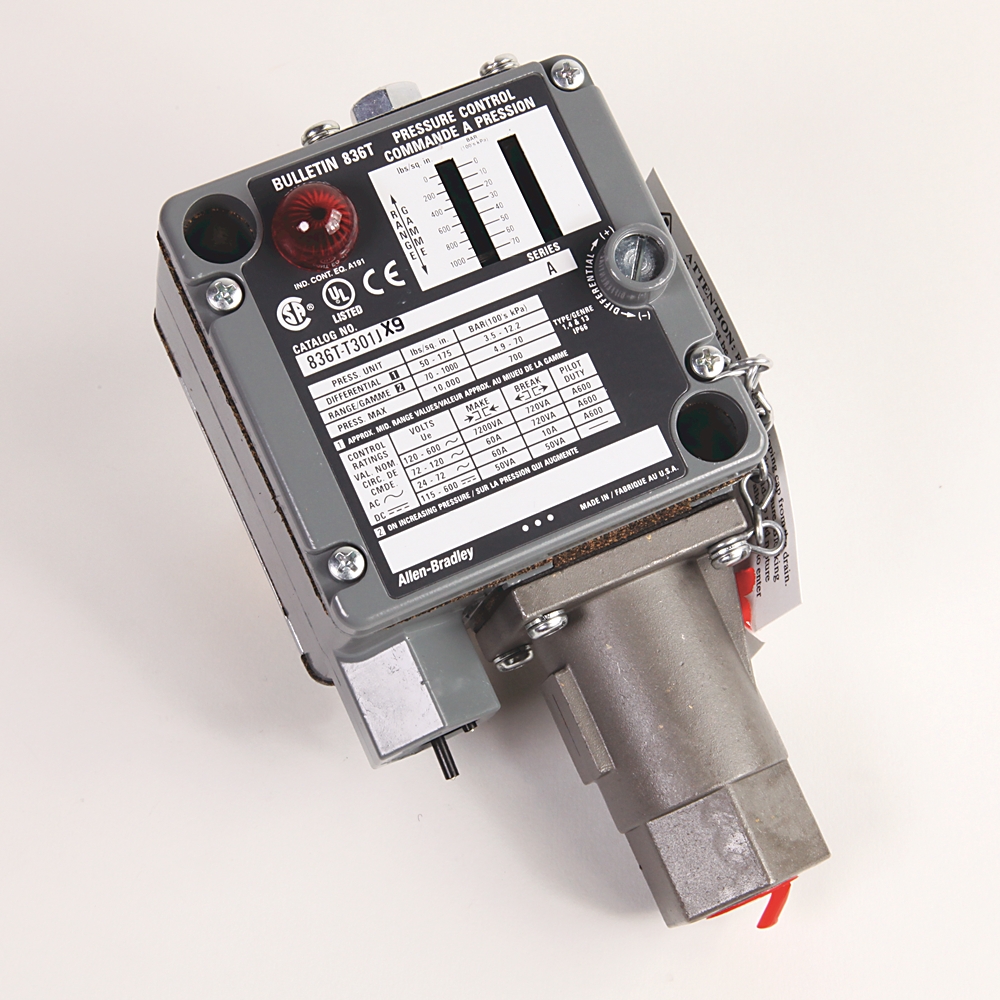

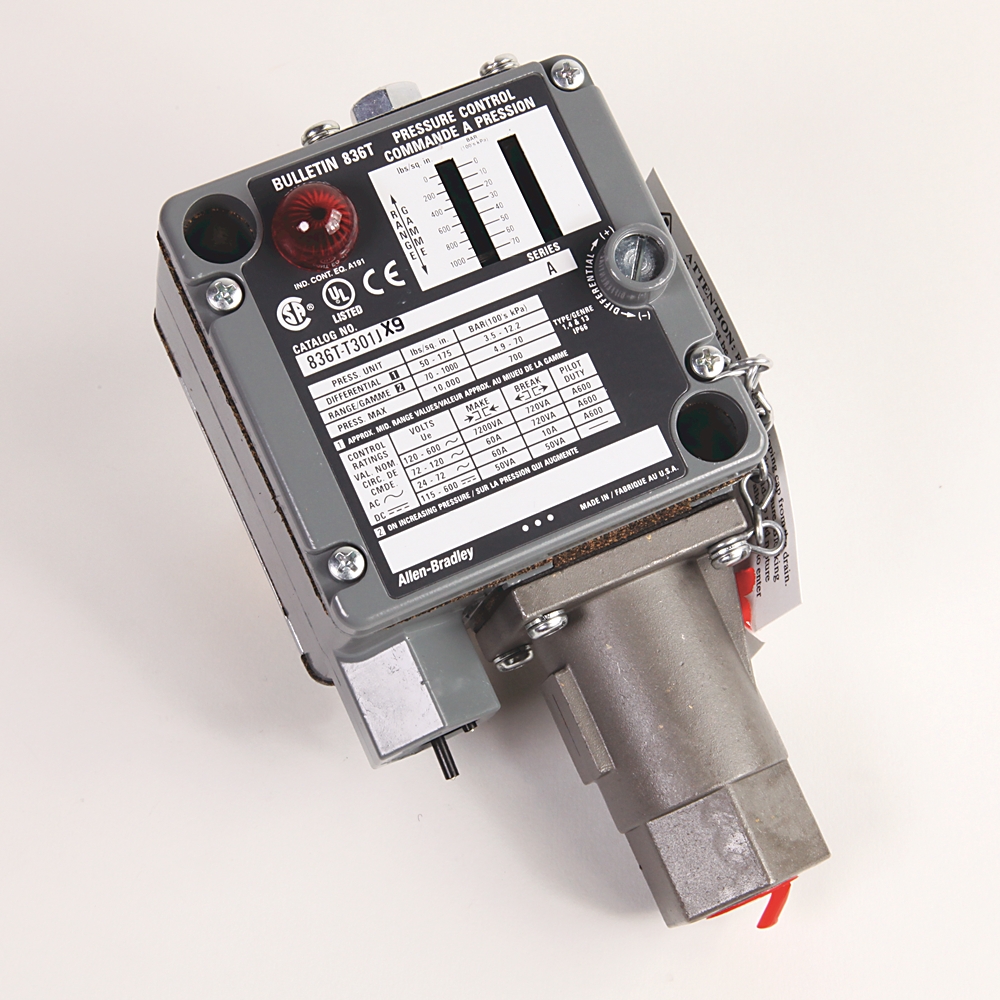

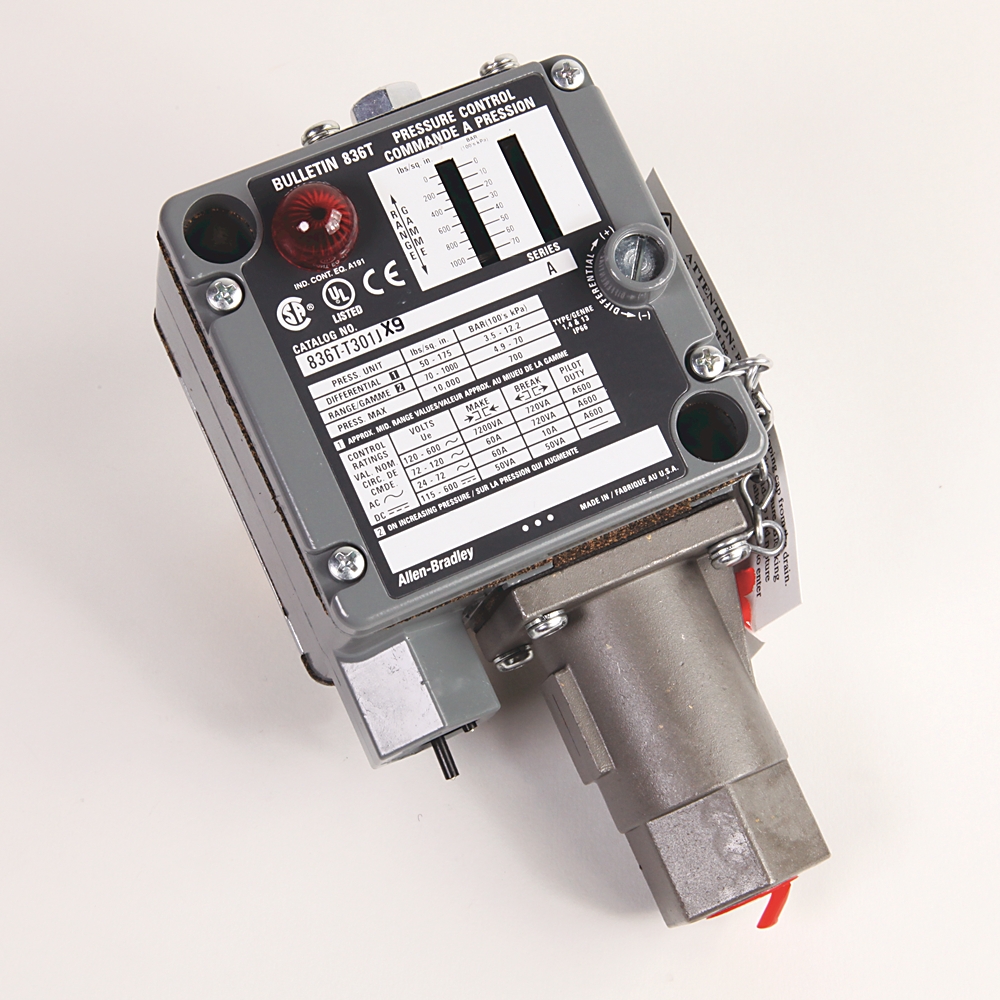

836T-T301J

Electro-Mech Pres Cntrl Sw

Product at a glance

Product at a glance

| Custom Trip or Reset Setting | Standard Trip/Reset Setting |

|---|

| Explosion-proof | False |

|---|---|

| Style | Pressure control |

| Enclosure type | Type 1, 4 & 13 industrial use |

| Operator type | Piston without seal |

| Actuator type | Piston without seal |

| Suitable for water | True |

| Suitable for oil | True |

| Degree of protection (IP) | IP66 |

|---|---|

| Depth | 76.7 mm |

| Height | 182 mm |

| Occasional surge pressures, max | 10000 psi |

| Adjustable differential | 75 psi |

| Adjustable operating range | 70 to 1000 psi |

| Pressure connection | 3/8 in. N.P.T.F. female pipe thread SAE 7/16-20 UNF-2B thread O-ring boss seal SAE 9/16-18 UNF-2B thread O-ring boss seal |

| Electrical connection | Plug |

|---|---|

| Rated operational current, break | 720VA @ 72...120V AC |

| Rated operational current, make | 7200VA @ 120...600V AC |

| Utilization category | IEC: AC-15, DC-13, NEMA: A600 |

| Customization | Standard trip/reset settings (the maximum operating range and minimum differential will be factory set for the pressure control switch.) |

| Contact block modification | S.P.D.T. 2-circuit contact block-standard |

| Operating temperature | -22 °F |

|---|---|

| Storage temperature | -22 °F |

| Drawings | |

|---|---|

| 3D STEP Model (STP) | Download (ZIP) |

| Drawings |

|---|

| 3D STEP Model (STP) Download (ZIP) |

| Type | Resource | Publication |

|---|---|---|

| General | Technical Data | -- |

| General | Repair Parts List | -- |

| General | Enclosure Dimensions | -- |

| General | Product Cutsheet | -- |

| Technical Data | 836-td001_-en-p | 836-TD001 |

Looking for more documentation?

Find curated technical documentation for this product in the Technical Documentation Center, or search our full Literature Library.

Search the Literature Library

Looking for more Technotes?

Find questions and answers from Rockwell Automation technical experts for this product in our Knowledgebase.

Search Knowledgebase

Technical Specifications

| Custom Trip or Reset Setting | Standard Trip/Reset Setting |

|---|

| Explosion-proof | False |

|---|---|

| Style | Pressure control |

| Enclosure type | Type 1, 4 & 13 industrial use |

| Operator type | Piston without seal |

| Actuator type | Piston without seal |

| Suitable for water | True |

| Suitable for oil | True |

| Degree of protection (IP) | IP66 |

|---|---|

| Depth | 76.7 mm |

| Height | 182 mm |

| Occasional surge pressures, max | 10000 psi |

| Adjustable differential | 75 psi |

| Adjustable operating range | 70 to 1000 psi |

| Pressure connection | 3/8 in. N.P.T.F. female pipe thread SAE 7/16-20 UNF-2B thread O-ring boss seal SAE 9/16-18 UNF-2B thread O-ring boss seal |

| Electrical connection | Plug |

|---|---|

| Rated operational current, break | 720VA @ 72...120V AC |

| Rated operational current, make | 7200VA @ 120...600V AC |

| Utilization category | IEC: AC-15, DC-13, NEMA: A600 |

| Customization | Standard trip/reset settings (the maximum operating range and minimum differential will be factory set for the pressure control switch.) |

| Contact block modification | S.P.D.T. 2-circuit contact block-standard |

| Operating temperature | -22 °F |

|---|---|

| Storage temperature | -22 °F |

Drawings

| Drawings | |

|---|---|

| 3D STEP Model (STP) | Download (ZIP) |

| Drawings |

|---|

| 3D STEP Model (STP) Download (ZIP) |

Documents

|

Technical Data

General

-- |

|

Repair Parts List

General

-- |

|

Enclosure Dimensions

General

-- |

|

Product Cutsheet

General

-- |

|

836-td001_-en-p

Technical Data

836-TD001 |

| Type | Resource | Publication |

|---|---|---|

| General | Technical Data | -- |

| General | Repair Parts List | -- |

| General | Enclosure Dimensions | -- |

| General | Product Cutsheet | -- |

| Technical Data | 836-td001_-en-p | 836-TD001 |

Looking for more documentation?

Find curated technical documentation for this product in the Technical Documentation Center, or search our full Literature Library.

Search the Literature Library

Accessories

Technotes

Looking for more Technotes?

Find questions and answers from Rockwell Automation technical experts for this product in our Knowledgebase.

Search Knowledgebase

Loading

Copyright ©2025 Rockwell Automation, Inc.