A digital blueprint for sustainable operations

As the global imperative for more sustainable business models gathers momentum, companies across the heavy industry sector are recognising improved sustainability as a key priority.

We offer extensive expertise in consulting and implementation of reliable digital solutions in extreme environments, designed to help achieve sustainability targets for you and your customers:

- Reduce greenhouse gas emissions

- Improve carbon capture

- Minimise downtime

- Increase asset lifecycles

- Cut installation, maintenance and engineering costs

- Boost productivity, efficiency and quality

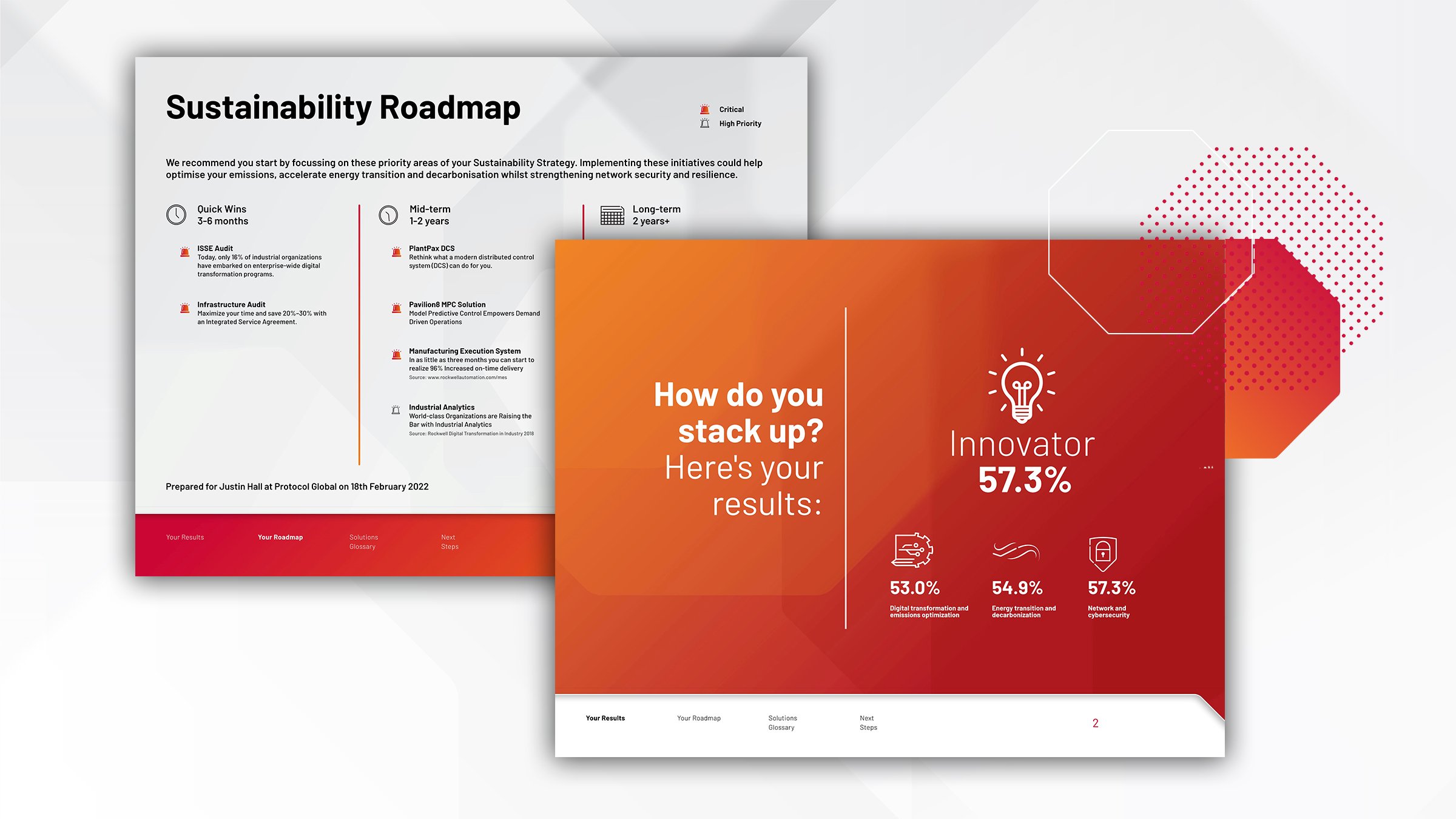

Online assessment tool

Build your personalized Sustainability Roadmap now and assess:

✓ Digital Readiness: How you stack up as an organization?

✓ Applications & Technology: What are your recommended solutions?

✓ Next Steps: Uncover your quick wins and long-term opportunities

Oil & Gas

Solving challenges from the reservoir to refinery with Sensia Digital Solutions

With the majority of oil and gas industry leaders working towards net-zero emissions by 2050, discover how Sensia Digital Oilfield can play a key role in implementing more sustainable upstream operations.

- Increase asset lifecycles through predictive analysis and maintenance

- Improve maintenance with augmented and virtual reality capabilities

- Assess and reduce CO2 emissions, and improve carbon storage and utilisation

Discover how Sensia helps upstream oil and gas companies to improve profitability while cutting energy consumption.

Mining, metals and cement

Smart solutions to increase energy efficiency

As many companies within heavy industries seek to reduce natural gas usage and cut carbon emissions in line with their energy reduction targets, discover how our digital solutions can help to:

- Reduce energy usage through advanced process control

- Cut MRO costs and improve storeroom processes and practices

- Optimise efficiency through real-time performance and operating data

- Identify obsolscence risks and execute modernisation projects

- Avoid downtime due through predictive maintenance

Explore how digitalisation can help your industry hit its key sustainability objectives.

Water treatment

Combine sustainability and compliance with advanced process control solutions

Energy efficient water treatment, desalination and recycling all require a fully integrated plant-wide process control solution. Discover how our digital technology help reduce energy use, engineering time, installation and maintenance costs by providing operators with real-time insights on:

- Performance

- Maintenance

- Safety

- Finances

- Total lifecycle costs

Compare the benefits.

Chemical

Boost energy efficiency, asset performance and regulatory compliance

As chemical companies navigate the challenge of energy reduction while maintaining productivity and compliance, discover how our process control systems can help to:

- Optimise performance and reduce downtime through predictive maintenance

- Drive operational efficiency with real-time data analysis

- Gain increased visibility for improved decision-making

- Improve asset utilisation and energy reduction with a better understanding of safety, environmental and quality data

Explore how a connected chemical production solution can improve energy reduction for your company.