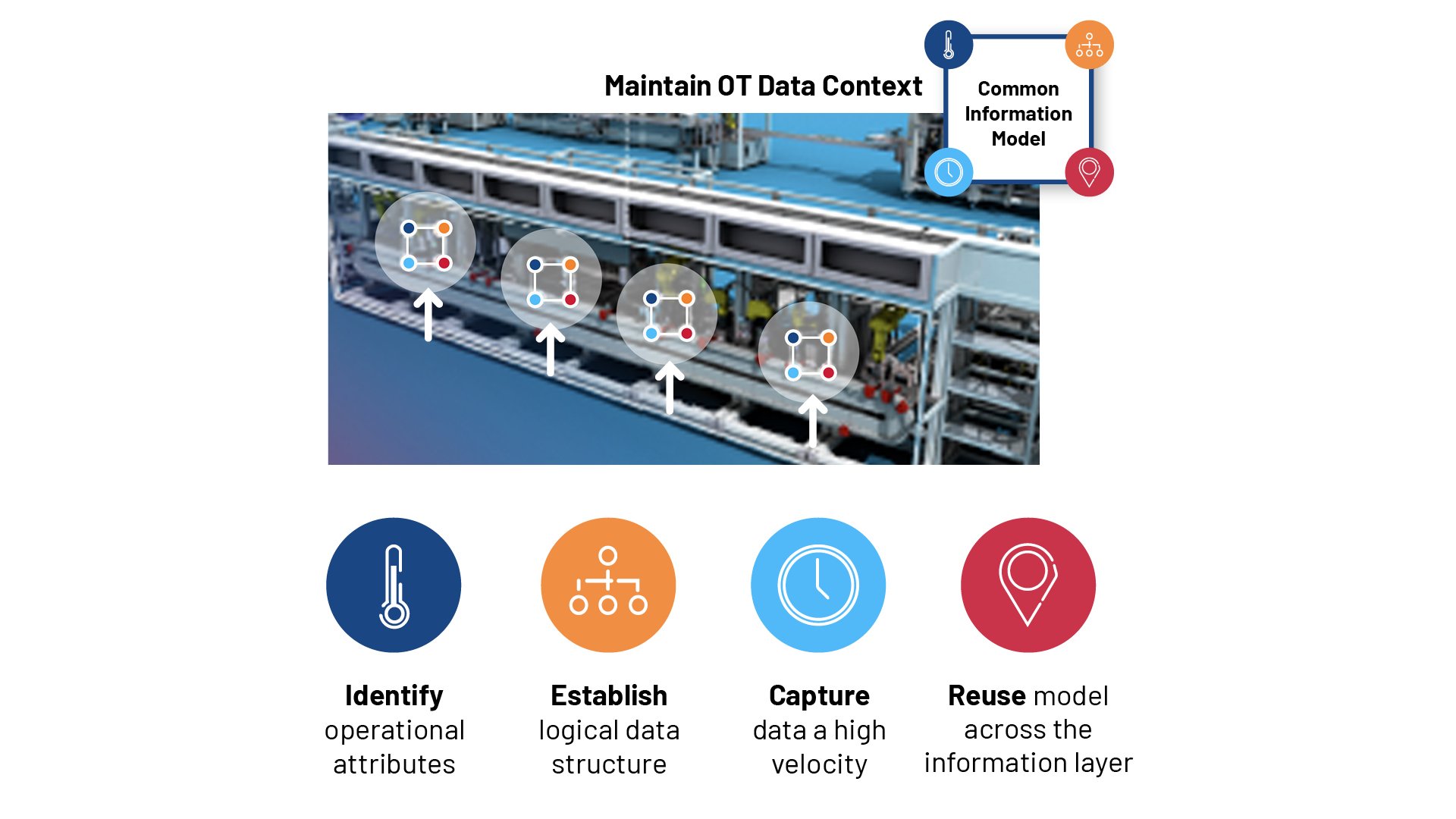

Industrial data is generated in such volumes and high speeds that it’s difficult to capture accurately. Even if you could, its use is likely limited by lack of both context and consumability. With operational data locked in disparate devices or siloed in systems of record, data scientists expend significant effort on data preparation and are hard-pressed to extract actionable industrial performance insights.

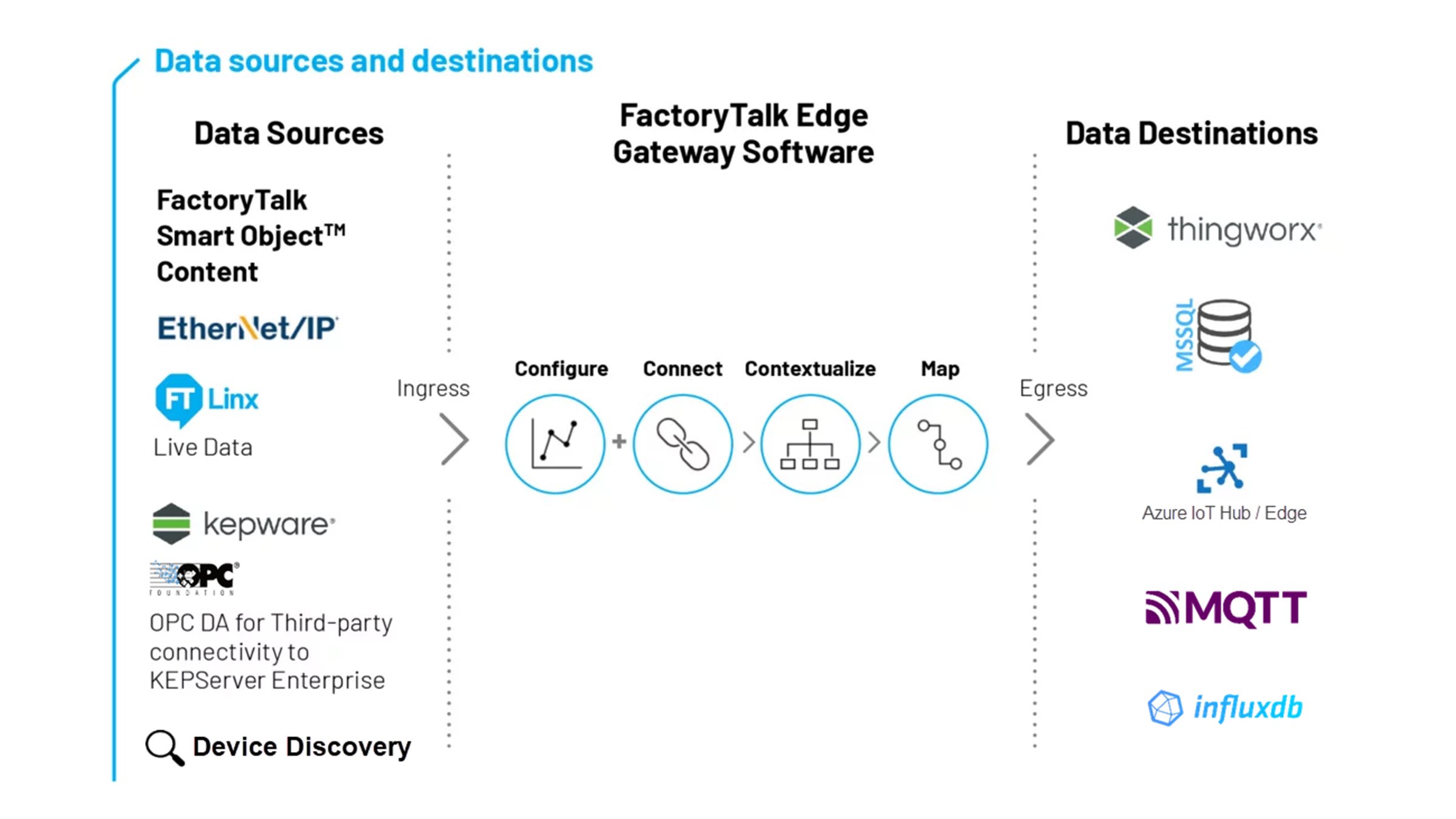

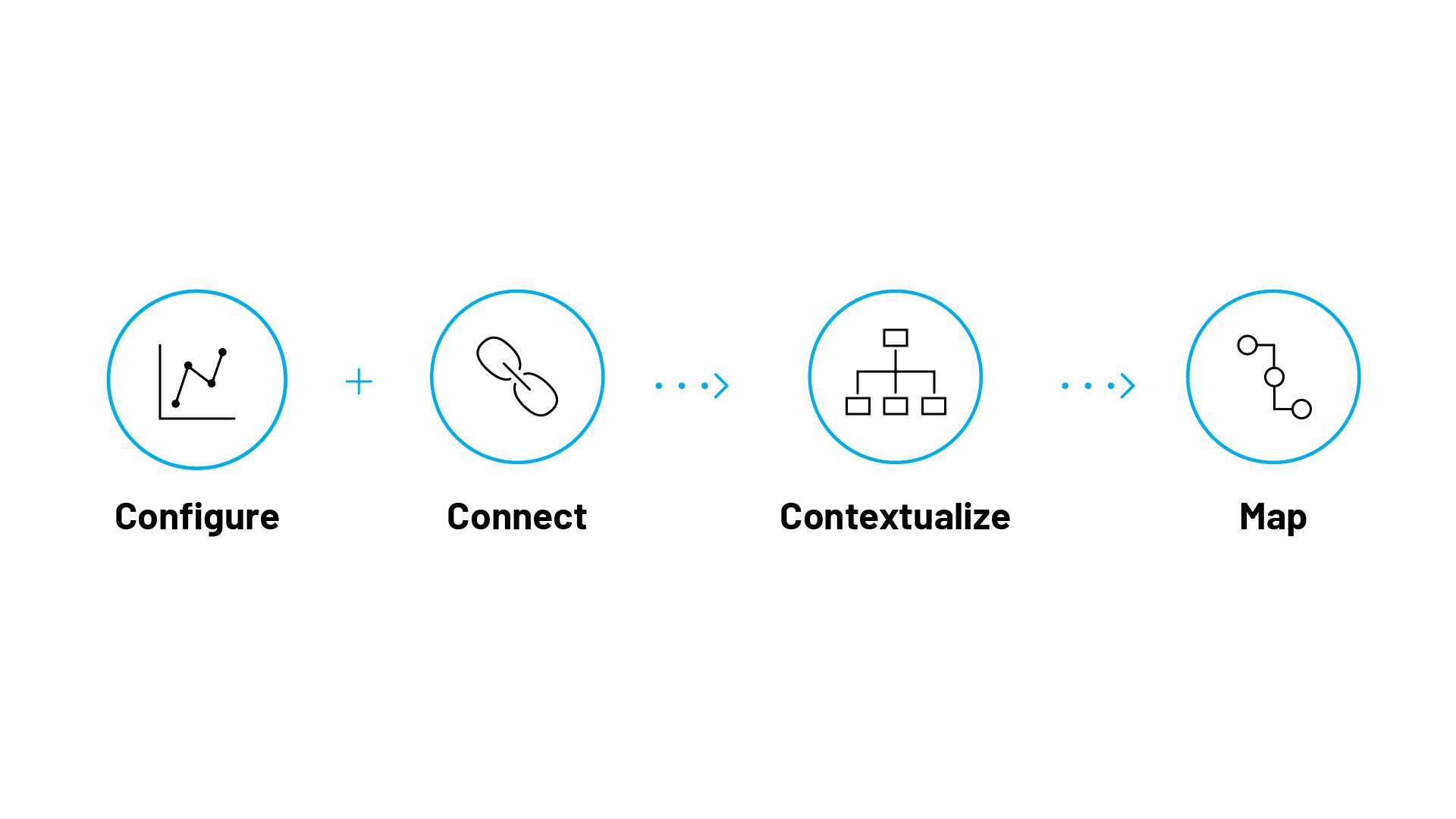

FactoryTalk® Edge Gateway™ software addresses these challenges, unlocking actionable plant and enterprise-level insights to accelerate IIoT digital transformation. It simplifies and automates collection, contextualization, and organization of industrial equipment data across machines, devices and automation assets at the source itself—enabling high data integrity from the outset. It provides the right foundation to drive edge-to-cloud IT/OT convergence at the enterprise level so that everyone from the shop floor to the top floor can make smarter decisions.