Recommended For You

Challenge

- Upgrade SCADA system to improve Hamilton City Council’s ability to securely store, analyse and report operational data

Solutions

- FactoryTalk Historian SE collects and stores data from all levels of the organisation

- FactoryTalk VantagePoint® EMI enables the organisation to view the information contributing to operational performance

- FactoryTalk AssetCentre provides secure access to the organisation’s system by managing contractor use and changes to the system

Results

- Smooth transition/migration to FactoryTalk architecture - Products including FactoryTalk View SE, FactoryTalk Historian, FactoryTalk Vantage Point, FactoryTalk Asset Centre and FactoryTalk ViewPoint, successfully installed

- Improved ability to comply with water regulations in a more efficient manner - Enhanced visibility into the production process for real-time and historical reporting and analytics Pre-validated data collection and storage ensures only accurate information is included in reports Web-based portal for reporting helps maintain a single for data

- Increased accessibility to reliable data - Access to 10 years of data storage, satisfying compliance requirements Able to provide a wide range of reports, whether it is on a daily, weekly or monthly basis

- Added flexibility for personnel operating the upgraded system - Personnel have the ability to externally manage the system via tablets or smart phones

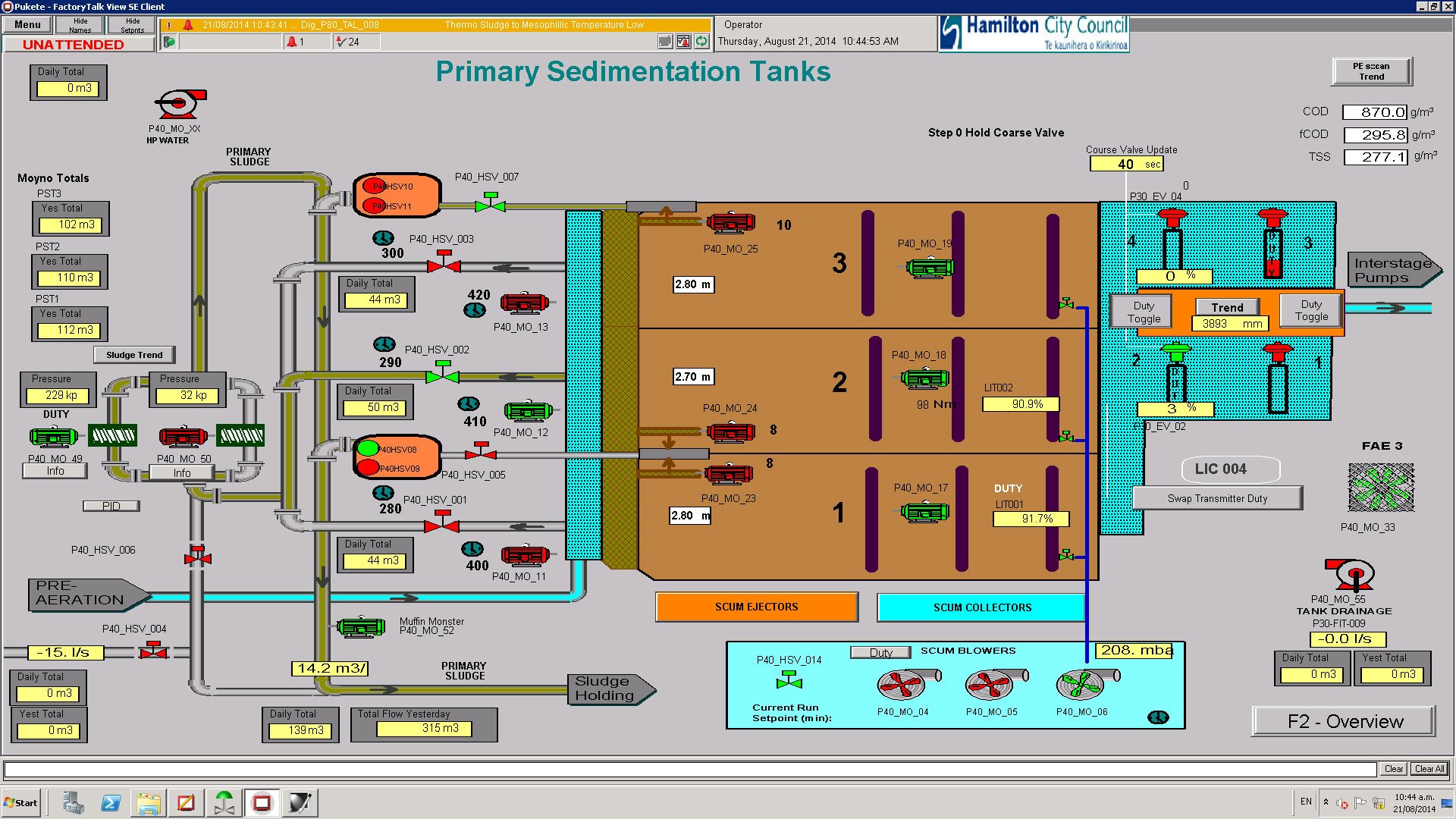

Waste Water SCADA Screen

The Waikato River — the longest river in New Zealand — supplies all of Hamilton city's water supply. Water is treated, distributed, and managed by the Hamilton City Council to ensure that when water reaches consumers, it is free from harmful organisms and meets water supply standards.

Hamilton's reticulated water supply system consists of one water treatment plant that provides potable water to eight different reservoirs located around the city through over 1000km of piping. The reticulated (piped) network delivers the water straight to the taps of consumers. Every second of each day, Hamilton City Council produces an average of 2,385 glasses of high quality drinking water to over 51,000 homes and industrial premises.

The council is also responsible for the operation of the Pukete Wastewater Treatment Plant (WWTP) — Hamilton's only wastewater treatment facility. This plant services a region that has grown rapidly in recent decades to have a population in excess of 150,000. Like the city, the Pukete WWTP is continually developing, in its case to improve operational performance and maintain compliance with a changing government regulatory environment.

Leveraging the FactoryTalk® Integrated Production and Performance Suite from Rockwell Automation, Hamilton City Council implemented an upgrade to their supervisory control and data acquisition (SCADA) system at the plant, enhancing the ability of key stakeholders to make informed decisions, improve performance efficiency and meet regulatory compliance.

Meeting Compliance and Productivity Requirements

Safe drinking water, available to everyone, is a fundamental requirement for public health. In 2008, the New Zealand Ministry of Health issued revised drinking water standards.

To comply with these regulations, it is the responsibility of water treatment facilities to track, save and provide monthly reports on water production, intake and discharge levels.

Crucially, the standards require that Water Treatment Plants retain operating data for 10 years. More than a decade ago Rockwell Automation provided the council with the software suite for its previous supervisory control and data acquisition (SCADA) system. However, the RSView® 32 system had become outdated over time and inefficient for compliance with modern-day regulatory requirements set out by the New Zealand Government.

With its previous SCADA system the council had often recorded data manually before transferring this information into Microsoft® Excel® spreadsheets for reporting. A faster, more accurate and automated reporting system was needed, and one that could rapidly generate pre-determined reports automatically for sharing with authorised groups.

“Our previous system was outdated and we required an upgrade to help simplify the process of complying with current water regulations in New Zealand. Not only that, but we identified the potential for improving operational efficiencies at the plant by implementing an integrated system that aims to increase productivity and reduce down-time,” said Gary Pitcaithly, automation and electrical manager at Hamilton City Council.

A key aim of the upgrade was to deliver a system with the ability to retain 10 years of data in a stable and reliable manner. At the same time, the system would need to provide operational efficiencies compared with the previous operating system, while also maintaining a secure environment only accessible by authorised stakeholders.

To improve on this process, Hamilton City Council engaged Rockwell Automation to provide the latest versions of the FactoryTalk software suite as the integral element of an upgrade to its system. According to Prasad Nory, industry manager – South Pacific at Rockwell Automation, “FactoryTalk Historian and FactoryTalk Vantage Point are increasingly becoming standards in the water/wastewater industry – especially with the need for compliance to changing drinking water standards. Also, FactoryTalk Historian ME has been used by some councils in their pump stations to store data locally to take care of communication failures and meet compliance.”

“By upgrading to the FactoryTalk suite the key benefits identified by council included: superior reporting for compliance to government regulations, improved system reliability and stability, and reduced risk when contractors are onsite to undertake modifications or further expansions.”

The FactoryTalk software suite delivers a real-time exchange of information throughout organisations, a critical element that allows for more informed business decisions, improved responsiveness, increased productivity, reduced costs and ease of compliance with regulations.

Implemented in-house by Pitcaithly, Hamilton City Council upgraded the WWTP's system over six months to include the Factory View (SE), FactoryTalk Historian, FactoryTalk VantagePoint, FactoryTalk AssetCentre and FactoryTalk ViewPoint applications. The Rockwell Automation Customer Support and Maintenance team provided support to the council during the upgrade, particularly for the migration from Historian Classic to FactoryTalk Historian.

The long-term storage and reporting capabilities required to comply with water standards are provided by FactoryTalk Historian and FactoryTalk VantagePoint. Data is stored in the Historian server for the required 10 year retention period and is easily accessed for analysis and reporting purposes. FactoryTalk VantagePoint is used by the plant to schedule and produce automatically generated reports providing information on periodical water consumption, discharge, intake, water quality and storage levels.

FactoryTalk AssetCentre provides improved contractor control, change management and storage capabilities. Most importantly, the plant is now positioned to efficiently comply with water regulations in New Zealand, including the storage of data and records for 10 years.

Delivering Fresh Water and a Clean Environment

The benefits of the new Integrated Architecture® solution will help the plant supply fresh drinking water and a clean environment to residents of Hamilton for many years to come. According to Pitcaithly, historical and reporting data is now available more quickly and accurately following implementation of the FactoryTalk suite, as the council had envisioned prior to the upgrade.

“The upgrade has delivered greater ease of use of our system throughout the WWTP. The new Historian is superior in how it stores data and makes generating information for vital reports a much more efficient task to undertake,” explains Pitcaithly. “The Vantage Point software allows us to develop reports at will, whether it is for compliance to water standards or for other needs. These reports can then be published as web-based reports that are available for anyone authorised to view them.”

Another key result of the upgrade has been the flexibility it has added for personnel operating the system at the WWTP. “The FactoryTalk software suite has enabled our team to be more flexible with their time, as we are now able to edit or update reports as we go.

We now simply store our data directly into Historian and the data spreads directly from the PAC (programmable automation controller) to a human interface. This data is incorporated into spreadsheets for us to interrogate, whether it is on a daily, weekly or monthly basis, to tell us if we've had a breach in turbidity or if chlorine levels aren't what they should be,” said Pitcaithly.

The flexibility extends to the ability of system users to remotely access the software from tablet computers or smart phones. “The team has tablets and smart phones that can basically access FactoryTalk View anywhere in the world – if they are out of the office or on-call the system can be easily accessed and key changes made,” concludes Pitcaithly.

With the FactoryTalk software suite delivering new found operational potential for the plant, the council is planning to continue to update and improve its system further in the coming years utilising these capabilities.

The results mentioned above are specific to the Hamilton City Council's use of Rockwell Automation products and services in conjunction with other products. Specific results may vary for other customers.

Published September 25, 2015