Tom Dufton has worn many hats over the span of his 20-year career. While he started out as a licensed red seal 309 electrician, he now works as a maintenance/project manager at Perth County Ingredients (PCI), where he is fully honed in on introducing automation.

Tom has been hard at work modernizing the PCI facility he’s worked at since 2017, where he’s implemented a building automation system (BAS) and a computerized maintenance management system (CMMS). Implementing two plant-wide systems over a three-year span is no small feat. But the results speak for themselves:

- A 54% drop in reactive maintenance

- A 47% reduction in after-hours call-ins

- A $40,000 decrease in maintenance costs

Tom has continued to roll out automation at seven additional facilities and has introduced condition-monitoring tools to help him and his team save time, collect better data, and improve the health of equipment. Let’s take a look at his roadmap to success.

Fighting fires all day, every day Tom joined PCI’s dried egg processing facility as a contractor back in 2012, so he already had in-depth knowledge of the plant when he took on his current role in 2017.

“When I started [full time], there was a large need for us to upgrade our facility. We needed new boilers, new chillers, that sort of thing,” says Tom. What’s more, the maintenance team was wasting time and resources. 100% of the maintenance was reactive—meaning the team couldn’t move beyond trying to put out fires all day.

Tom knew his facility was in desperate need of a solution that could let them get ahead of maintenance and plan it, rather than reacting to it. His team also had little insight into after-hours emergency calls. The maintenance team would get alerted, and someone would have to respond, whether it was pressing a reset button or a repeat problem that could easily be solved.

Using Fiix to tackle reactive maintenance and save time The facility’s BAS system was already in place, but Tom knew more was needed to get things under control. He needed solid CMMS software and made the choice to use Fiix, by Rockwell Automation. It didn’t take much to get started.

“It was quite simple,” says Tom about putting Fiix in place at his facility.

The minute you start adding assets, you start making work orders, you start making scheduled maintenance, your team stops relying on you for that day-to-day and asking ‘What would you like me to do today, Tom?’ Now you have that in the maintenance software.

Not only did implementing Fiix allow Tom to focus on managing the maintenance team, but it also gave him the value-added time to project manage a $4M CapEx investment for the facility.

As it turned out, Fiix was exactly the puzzle piece Tom’s facility needed. He started by providing tablets with the Fiix app to the entire maintenance team. The app allowed the team to log and look up work by scanning a QR code on an asset. It also gave them the power to access standard operating procedures (SOPs), old work orders, and the BAS in seconds. All of this helped to shave hours off of the time it took to troubleshoot a problem, especially when it came to managing contractors.

“We put WiFi throughout the entire plant, which has allowed us to use tablets and cell phones to access Fiix,” says Tom.

And when you have all that scheduled maintenance in the system with pictures and asset tags and so on, you can set contractors up with that information and your team doesn’t need to be disrupted.

Automating maintenance across the whole company The VP of operations at PCI noticed the success at Tom’s facility and asked Tom to start rolling out Fiix out at more facilities. This led Tom to implement the CMMS at seven other L.H. Gray facilities across the country.

“The automation within our facility has basically allowed us to run multiple operations from one location,” says Tom about the benefits of this project.

"I get email alarms along with the production manager, so our fingers are always on the pulse of the facility. Without being there, you still know what's happening."

“Putting in these measures for automation has allowed us to bring down the number of people who need to be in one place at one time,” says Tom.

What’s more, the control that Fiix gives Tom has allowed him to roll out the remaining implementations remotely, with no plans of slowing down anytime soon.

“If you’re standing still, you’re falling behind,” says Tom. “We are constantly driving for more automation and growing.”

The search for maximum maintenance efficiency Tom’s strategy was working. Reactive maintenance was down 54% and after-hours call-ins were down 47%. But there was still plenty of room for improvement.

Preventive maintenance was still being scheduled based on old habits. A compressor would be checked every few weeks, even if it was operating perfectly. Oil changes relied on whether technicians thought the oil was good or bad. And inspections were still being done manually. The team was spending hours checking meter readings and logging data every week.

And while asset failure and fire fighting were down, Tom knew tasks like these were costing his team time and money they could be using somewhere else. So he set out to cut them from the schedule.

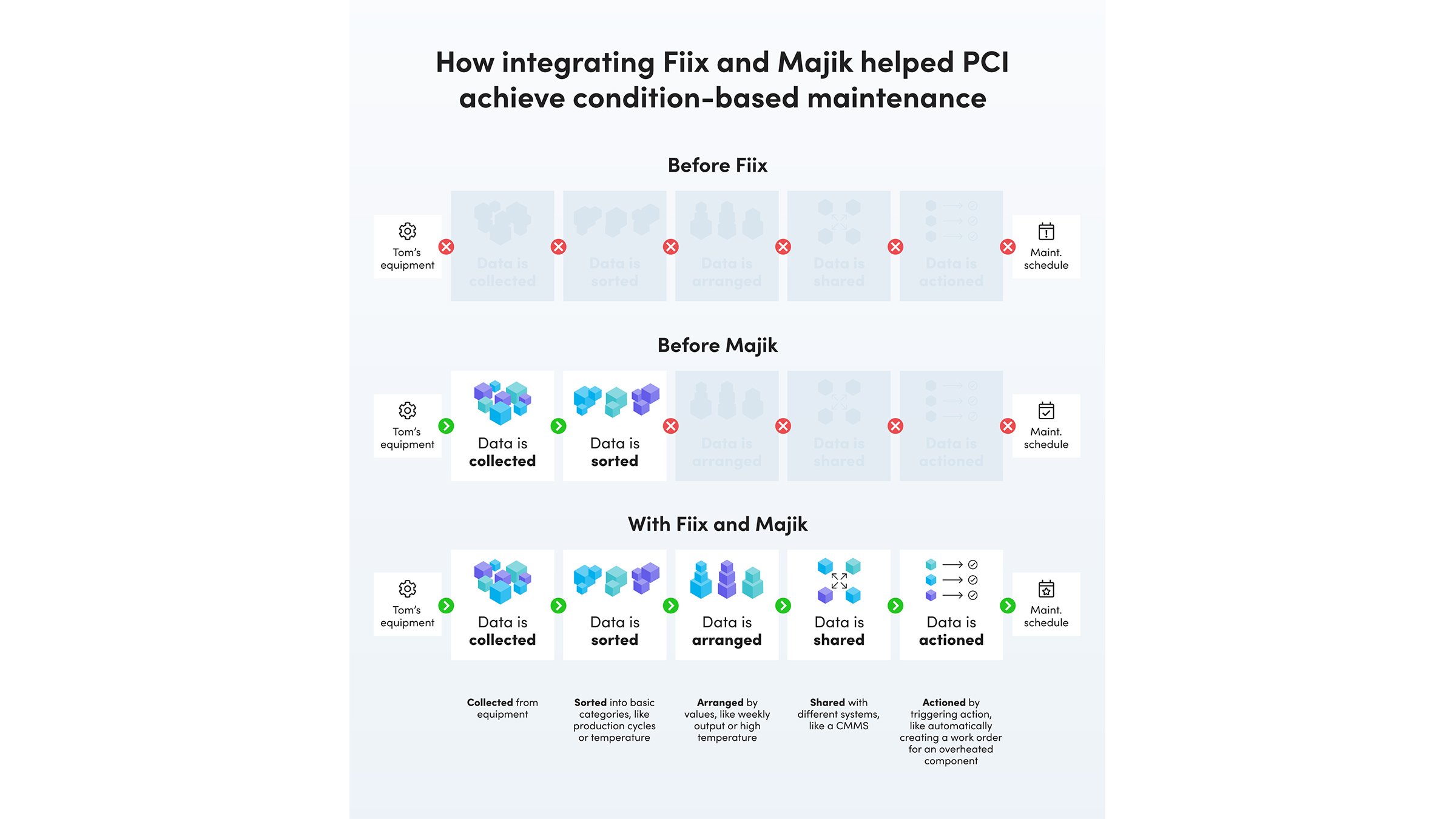

There was just one problem—Tom didn’t have the information he needed to pinpoint those jobs or the tools to automate them. So he teamed up with Fiix’s integration partner Majik Systems to find a solution.

Saving $40,000 a year with condition-based maintenance With the help of Fiix and Majik, Tom connected the facility’s PLCs to his CMMS. This gives him the power to collect real-time information about the condition of equipment. Now he can track vibration, temperature, or any other machine reading.

But this data would be next-to-useless without the link between Majik and Fiix. This connection allows asset data to flow into Tom’s CMMS without him lifting a finger. If a reading hits a certain threshold, a work order is created.

The best part is, the integration was done remotely. And it took only two weeks from start to finish (with less than a day’s work for Tom and his team).

“We now have alarms that are tripped and warnings to operators that if action is not taken or maintenance isn’t contacted that it could shut them down,” says Tom.

"The plant runs 24/7, but maintenance is only here Monday to Friday. So it’s very important that we’re capturing all this information … because when we see a change in the condition of an asset, we need to take action."

The results have been immediate and significant. It’s been nine months since Tom put Majik in place and has already cut costs by $40,000 from decreasing breakdowns and shedding unnecessary jobs from his team’s to-do list. This is a 300% return on his original investment in the project.

We’ve seen old issues fall off. Things like motor pumps and bearings replacements. They’ve all decreased. And the value of connecting Fiix and Majik will only increase as Tom continues to find ways to optimize his maintenance schedule and help his company make smarter CapEx decisions.

“[With Fiix and Majik] you can collect all the work orders and repair costs for everything and you present that to your owners and you can say, we can continue down this path or we can get a new one,” says Tom.

And that’s a piece of ROI. By gathering the data, you’re able to give people real-world information and provide a snap-shot of the facility and tell them where it’s headed.

Published May 23, 2022